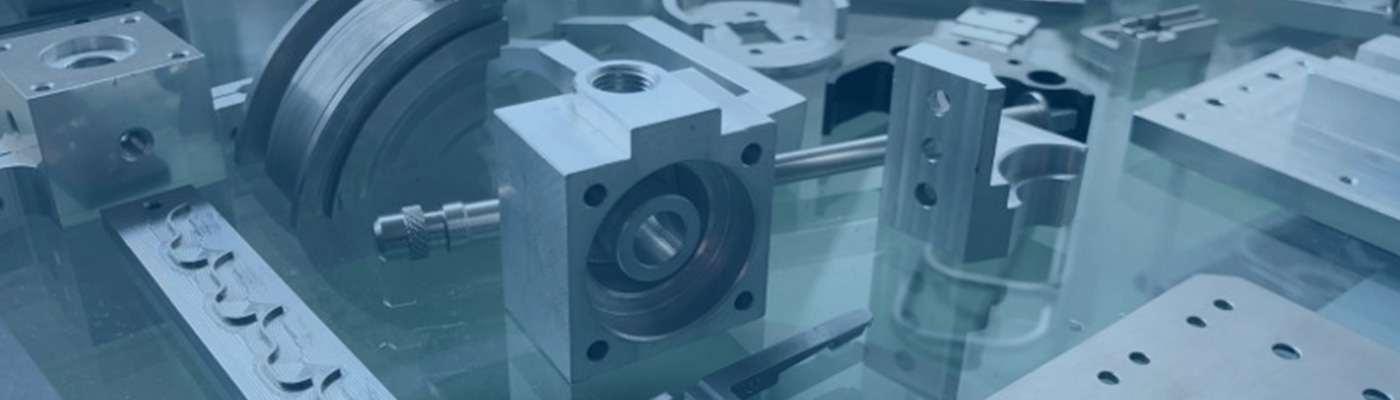

Metal Parts Processing

Metal Parts Processing

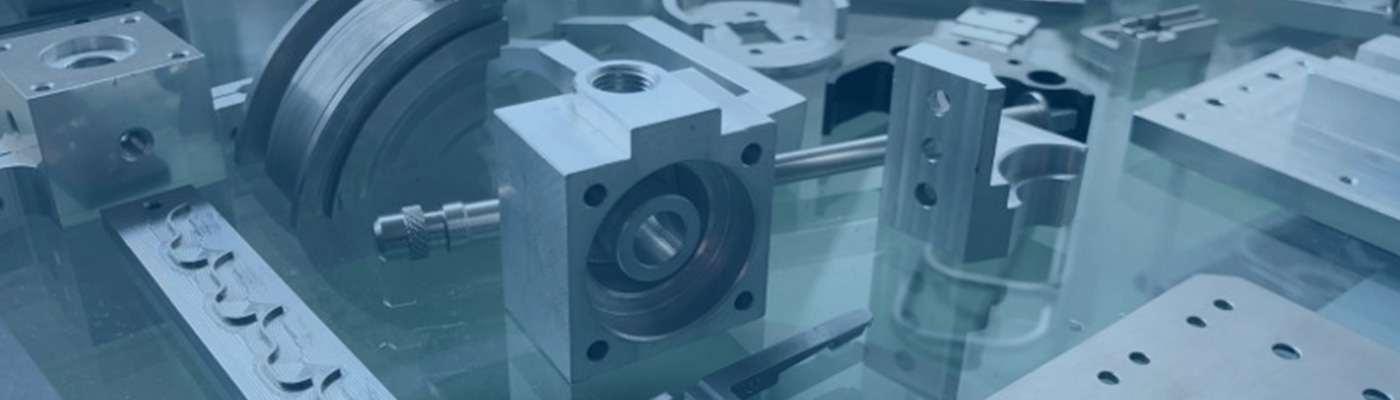

From part prototyping to mass production processing

J.P.F. Co., Ltd. accepts requests for small lots such as prototype processed products and single processed parts.

We receive a wide range of requests for processed parts, including mass-produced processed products for small items.

We have built up a track record by providing finished products to our customers as machine parts, from procurement of materials to surface treatment.

Our strength in metal parts processing is the production of technology.

By producing machines and collaborating with cooperating companies,

Our strength lies in our ability to produce products that combine the expertise of partner companies with the expertise of our own company.

Over the years, we have listened intently to the voices of customers who have trouble with delivery times and processing methods.

With the technology and knowledge backed by those experiences, we aim to further improve our services.

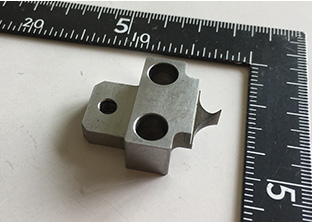

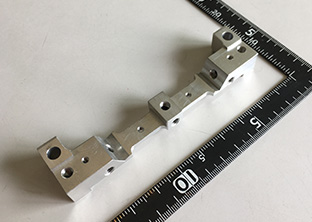

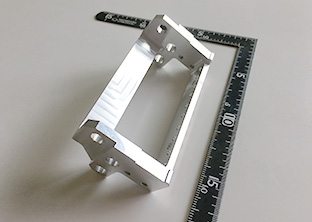

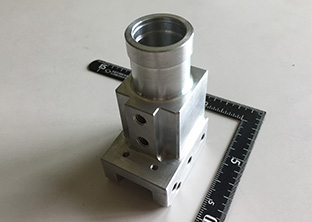

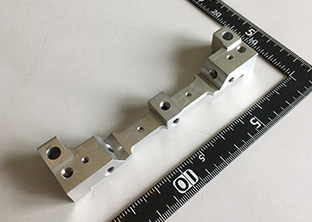

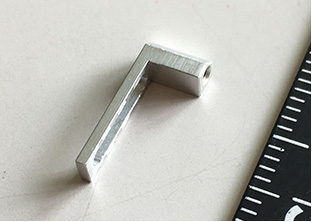

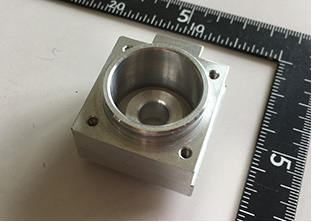

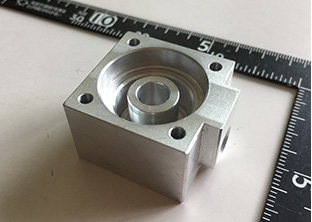

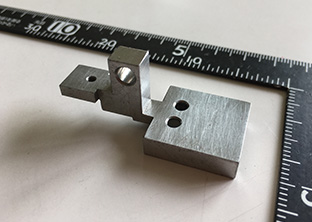

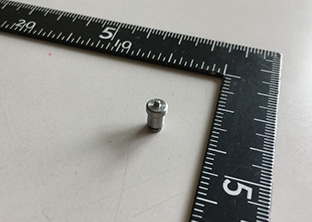

Prototype/single item processing example

Prototype products and single-item processed products are fully familiar with the characteristics of the machine and are used accurately.

Processing machines are the same as craftsmen, and there are processing that they are good at and processing that they are not good at.

When the craftsman sees the drawing, he grasps the details of the processing and selects the processing machine.

We perform high-quality processing by combining reliable processing machines and craftsmanship.

Material A5052

Material A1000

Material A5052

Material A6063

Material HAP40

Material SUS304

Material SUS316

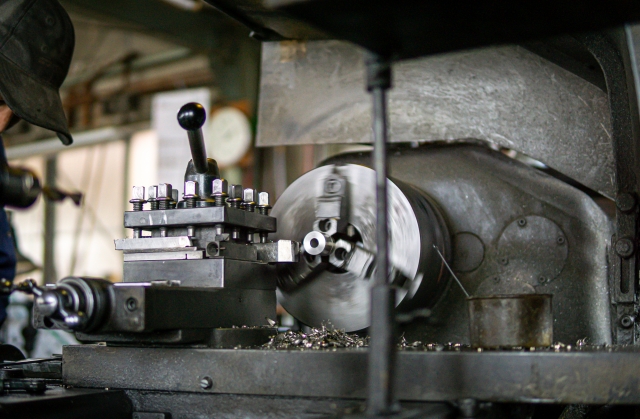

Examples of mass production processing

FANUC’s ROBODRILL is mainly used for mass-produced processed products.

Mass production requires craftsmen’s creative power, and by performing processing programming that makes use of their creative power, one person can use 2 or 3 machines in parallel, which can reduce costs.

Material A5052

Material A5052

Material A5052

Material A5056

Material A7075

Material A7075

Material S55C

Material SKD11

Material SKD11